The critically endangered Sumatran tiger is one of the rarest subspecies of tiger with a remaining wild population of approximately 300 individuals. Due to a combination of poaching, habitat loss and human conflict the Sumatran tiger population has suffered a staggering 95% decline in the last decade, placing it at high risk of extinction on the IUCN Red List.

ZSL London Zoo have been working across the globe in a major effort to improve the fate of the Sumatran tiger, culminating with a new flagship ‘Tiger Territory’ facility. Not only enabling the zoo to embark on a critical breeding programme, ‘Tiger Territory’ also allows experts to gain valuable information about the elusive creatures that can be applied to conservation projects in the field. Tiger Territory is intended to be a centre to match-make Sumatran tigers from around the world, with the first inhabitants scheduled to be Jae Jae and Melati. Selected by the global breeding programme for the critically endangered species and prized as Europe’s most genetically important pair of Sumatran tigers, their cubs would be the first to be born at ZSL London Zoo for over 15 years.

Robin Fitzgerald, Project Manager, ZSL London Zoo

Harry Everest, Project Manager, ZSL London Zoo

Mike Kozdon, Architect, Wharmby Kozdon Architects

Gavin Sayer, Associate, Dexter Associates

Andy Traynor, Head of Installation/Director, Base Structures

Andy Chiverton, Project Manager, Base Structures

For a project of such global significance the stakes were high for the new zoo structure. The primary focus was on animal welfare, conservation and the creation of the perfect environment for animal husbandry – rather than the creation of an architectural masterpiece. As Robin Fitzgerald, Project Manager at ZSL London Zoo summarised ‘Our goal was to seek out the latest technologies and designs that could match our husbandry and habitat requirements while still satisfying visitor needs.’

Key objectives were set out with a team of conservationists, tiger keepers and education specialists. From a habitat perspective the zoo enclosure clearly needed generous proportions, especially in height – the Sumatran tiger is a keen climber with a preference for observing its terrain from a high vantage point and can boast an impressive vertical jumping ability of up to five metres. The facility also had to meet strict husbandry requirements and be practical for everyday zoo keeper use. Capacity for future additions had to be factored in as well as the sustainability and energy efficiency of the enclosure. From a visitor perspective it was vital to offer a spectacular viewing experience with multiple perspectives, including a prominent, highly visible platform for the education department to deliver talks. All of this needed to be achieved within the existing constraints of the 186 year old site and adjacent architecture.

A team was assembled to turn this vision into reality that included Mike Kozdon of Wharmby Architects and specialist consultants including Base Structures and structural engineers Dexter Associates. Collaborating closely with the zoo, the team could apply the specialist knowledge that is necessary to turn the brief into not only a workable concept, but a flagship zoo enclosure.

A woven mesh structure was designed that could mould itself around the existing footprint shape and soar upwards into peaks, providing the necessary vertical jumping space. This design was not simply a response to the existing site geometry however. 90° angles were carefully and deliberately designed out to present sloping, organic lines to better reflect nature. A 3mm diameter cable woven 316 stainless steel mesh was selected with a 100mm x 100mm aperture – aesthetically the mesh would provide a thrilling experience for the public by virtue of its unobtrusive appearance. Floor to ceiling glass viewing panels topped with a fabric canopy would also allow the public to stand within millimetres of the tigers.

Tiger Territory was intended to be ultimate big cat exhibit for both visitors and the cats themselves. The dramatic form of the zoo enclosure creates a wonderful sense of drama when approaching Tiger Territory through the zoo grounds, yet the unobtrusive mesh allows the enclosure to simply fade away into the background when the tigers are viewed at close quarters. ZSL London Zoo’s brand new Sumatran tiger enclosure was given the royal seal of approval on Wednesday 20th March 2013, when it was officially opened by HRH The Duke of Edinburgh.

The Sumatran tiger enclosure was given the ultimate seal of approval on the 3rd February 2014 when a trio of healthy cubs were born to five year old Sumatran tigress Melati. Hidden cameras in the cubbing den allowed the zoo to remotely monitor the birth and the progress of the cubs 24 hours a day, with exclusive footage released on the ZSL You Tube channel (www.youtube.com/user/ZSLvideo.). The births are not only a huge achievement for ZSL London Zoo but also the international breeding program.

Lords cricket ground, owned by Marylebone Cricket Club, is regarded as the world wide spiritual home of cricket. To ensure the Ground remains not only world-famous but a truly world-class sporting venue, a multi-million pound overhaul was undertaken, part of which included the upgrade of the Mound Stand canopy which after eighteen years of sterling service had reached the end of it’s designed life span.

John Cutlack, Director Capita Symonds

Tony Hogg, Director, Tony Hogg Design Ltd

Mark Smith, Contracts Director, Base Structures

Chris Ives, Project Manager, Base Structures

We were briefed by Capita Symonds, the appointed representatives of Marylebone Cricket Club, to remove, redesign, manufacture and install the new tensile fabric roof over the Mound Stand, a monumental task that would not simply replace the old canopy but provide significant structural improvements through the use of more advanced materials and up-to-date design detailing. As such the replacement canopy would be expected to last significantly longer than the old one.

A fundamental part of the contract win was our ability to ensure the recycling of the old canopy and so we partnered with Serge Ferrari (suppliers of the fabric for the new canopy), who have developed and built the Texyloop PVC recycling factory in South Eastern France. The recycling of the old canopy led to Base Structures achieving a finalist Building award for Sustainability in 2006.

Base Structures were able to provide the client with a methodology that ensured we would meet the tight deadlines, budgets and planning restrictions. This was made possible through the accurate surveying of the existing structure to ensure the replication of the iconic shape, and through the use of innovative access methods. It was essential that the project was undertaken and completed in one closed season so that our works did not interfere with or delay scheduled cricket matches.

The first task was to remove the old canopy, in itself a huge job. The biggest problem faced by our team concerned how to fully access the canopy structure as it overhangs a busy main road and is closely neighboured by residential buildings.

The solution we identified required the use of Working Platform Nets. These netting systems are engineered to ensure the safety of the operatives working on and below them is not compromised and they proved to be incredibly cost effective by reducing the man hours needed working at height, when compared to traditional means of access such as scaffolding. Once the netting was installed by our fully qualified rope access team, non-IRATA trained personnel could then access the work areas in complete safety. The old canopy came down surprisingly quickly once the netting allowed easy access to the structure, especially considering the amount of fabric involved.

Next a detailed survey of the existing steelwork enabled our design department to accurately recreate the iconic structure within our specialist CAD software, from which we produced the cutting patterns and finalised the detail design.

It was necessary to redesign and upgrade all the fixtures and fixings on the existing structure to take into account advancements in tensile fabric over the previous eighteen years, ensuring that they were all brought up to current best practice standards. The new PVC membrane itself was a higher specification fabric than the original canopy, using higher quality PVDF lacquers to guarantee a longer life span. As part of this extensive upgrading process all the existing structural steelwork was repainted before the new canopy was installed.

The old canopy was originally made in sections that were joined together using metal fixtures. Taking advantage of the opportunity to redesign the canopy and to improve the aesthetics, the new 1400 sq metre fabric membrane was manufactured and installed as a single piece of fabric. This improvement resulted in no site joints along the front of the canopy, significantly enhancing the overall appearance.

Once manufactured the installation of the new canopy began in earnest; the fact our rigging team had removed the old canopy gave us a flying start when it came to installing the new one, since they already knew the structure inside and out. After the new canopy was lifted over the multiple masts in one piece, our rigging team made short work of the installation.

The entire project was successfully completed ahead of schedule and below budget, no easy task considering the scale and complexity of the project. The replacement canopy not only restored the stand to its former glory but also improved the aesthetics and expected life span of the structure. Marylebone Cricket Club were extremely happy with the refurbishment and continue to use Base Structures for regular maintenance of this most iconic of structures.

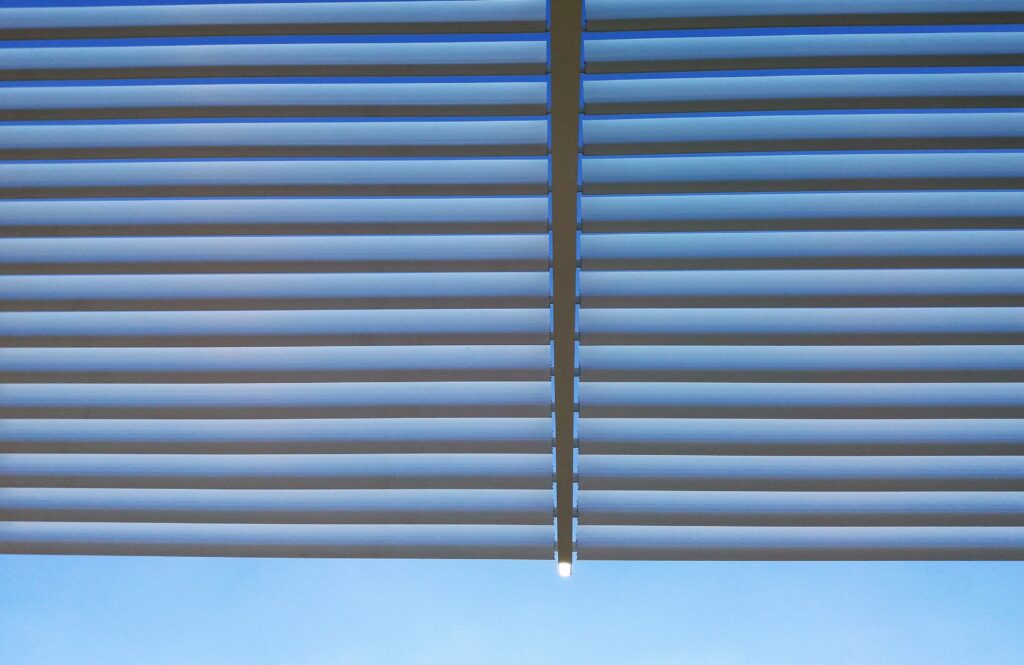

Lord’s Cricket Ground required a new awning to the Grandstand roof to replace the existing retractable blinds over the seated area. Following on from previous works we carried out for the MCC to their Mound Stand and Pavilion canopies, we assisted them in developing a louvre scheme to provide the necessary sun shading and give the stand a fresh look.

The new scheme consists of 384 light-weight aluminium louvre blades in bays of 16 and has been designed to reduce snow and wind loads. A solar survey was also carried out to calculate the optimum angle for the blades to prevent direct sunlight passing through onto the spectators below, whilst allowing maximum ambient lighting.

Due to the precious & hallowed Lord’s outfield, particular care was taken whilst our works were carried out. Light weight Spider MEWPS were deployed to reduce the impact and point loading on the pitch grass.

This is an exciting addition to our portfolio and showcases the extensive design and build knowledge we have in house that enable us to provide custom solutions for special projects.

Coleg Gwent is a college situated just outside Cardiff in Wales that prides itself on being a flagship provider of A-levels and vocational courses. A thorough refurbishment in 2010 has created an attractive and eco-friendly environment in which the students can academically further themselves, complete with solar panels, biomass boiler and rainwater harvesting.

To improve the recreational facilities for students the college wanted an exterior covered seating area, enabling the students to relax outside in comfort – even in the scorching Welsh summers and often damp winters. By choosing one of our standard structures, the Mendip Walkway, they managed to get the most from their budget. Despite being a pre-designed structure the Mendip Walkway can be extended ad infinitum, in this instance they required a length of four bays. If needed the structure can also accommodate changes in level and direction – standard has never been so adaptable. The lack of tie-rods on the steelwork means there are no trip hazards too, leaving only clean, sculptural lines for the students to relax beneath in style.

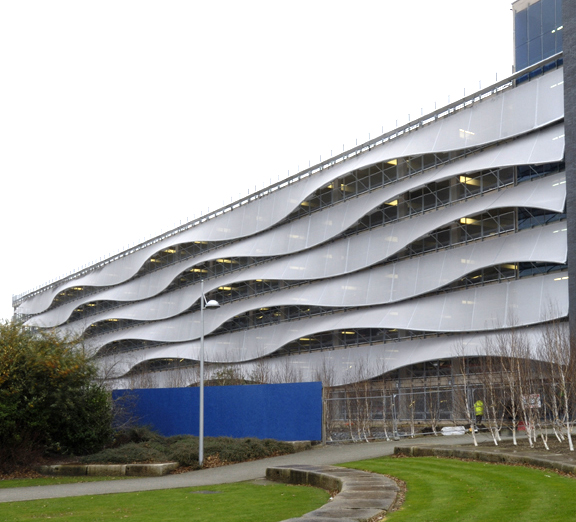

Cardiff Bay is Europe’s largest waterfront development. The Bay area was created by the Cardiff Barrage, one of the largest civil engineering projects in Europe during the 1990s and the subsequent regeneration of the area is widely regarded as one of the great success stories in the United Kingdom. As part of the continuing success story of Cardiff Bay, a newly built 1238 space multi-storey car park in a prominent location required status as a landmark building. The £11m car park was the first phase of a £150m development and utilises cutting edge 21st century design to reflect the rich nautical heritage of the area.

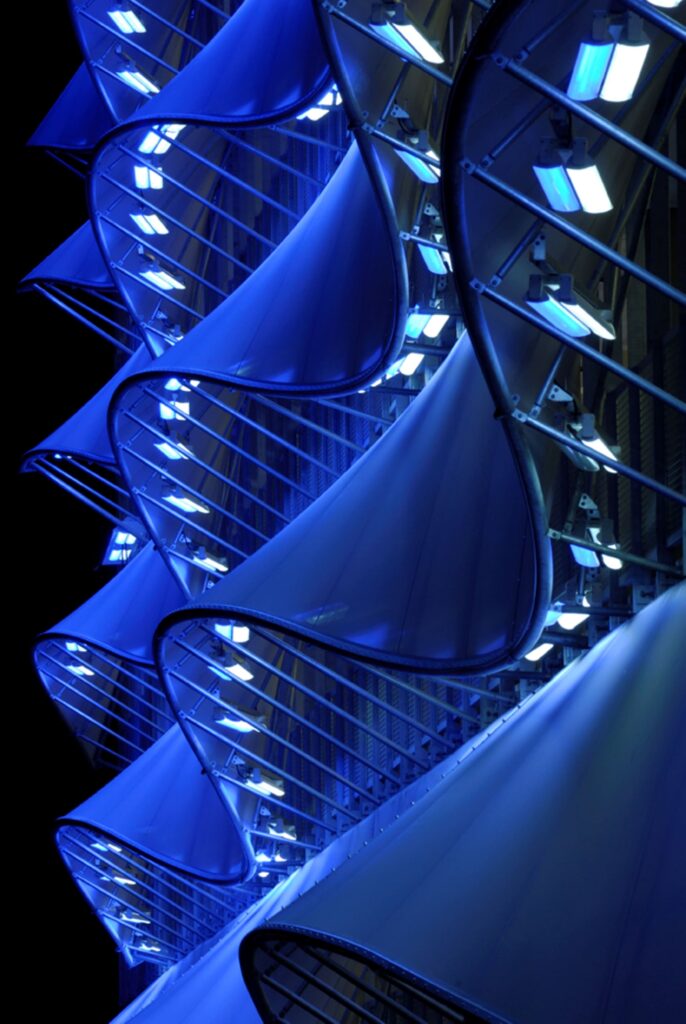

The rectangular, box like car park was to be completely transformed by a series of six 120m long scalloped tensile fabric ribbons running parallel across the entire width of building, a stunning contemporary design by Scott Brownrigg Architects. The pulsing waves of fabric cascading down the front of the car park bring an otherwise unremarkable building, formed entirely by it’s function, dramatically alive with movement and a dynamic flair that most car parks could only dream of! Base Structures were approached by main contractor McAlpine Construction to use our specialist skills to detail design, manufacture and install the tensile fabric structure and lighting system.

Base Structures were selected to bring this vision into reality due to our proven expertise and excellent relationship with the main contractor. As well as undertaking the detail design, manufacture and installation of the fabric facades, we also collaborated closely with a specialist lighting company to create the impressive lighting scheme.

A silver mesh PVC fabric was selected for a number of reasons that were crucial to the successful function of the facade. A mesh fabric allows light and air to filter through into the car park, ensuring the facade that clothes the front of the building does not create a dark and exhaust filled cavern. From inside the car park it is possible to see through the mesh fabric to the outside world, retaining an open feeling inside a ‘clothed’ building, further enhanced by the wave design which inherently creates sizable openings that also serve to improve the airflow.

Because Base were involved with every aspect of the project, from the detail design through to the installation of the fabric and lighting, the completion of the facade was completed in approximately 10 weeks, on budget and on time. The installation of the ‘wavy’ steelwork that supports the fabric was a simple process completed by a six man team working on scaffold. 120 meter long Halfen channel had already been cast into the concrete structure of the building front, requiring us to simply secure the necessary fixing bolts at specific distances before attaching the framework. The installation of the tensile fabric and lighting system was completed next using eight men and cherry picker work platforms for access, with an electrician required to complete the final wiring once it was all in place. To finish the installation four of our rope access specialists were used to fit the bird protection equipment, including wires and spikes, preventing nesting on the lighting units and fouling on the fabric canopy.

The car park has been dubbed the coolest car park in Cardiff, an easy achievement one may think. For any public car park to be labelled as cool in the first place however, speaks volumes about the success of this tensile fabric transformation. The combination of tensile fabric and lighting is an extremely powerful one, especially when used to metamorphosise a building with a colour changing, three dimensional canvas. As far as we are aware this car park is the only example of it’s kind in the world.

As part of the Government’s initiative to roll out academies across the UK, Nottingham University and Leicestershire businessman David Samworth co-sponsored the building of a brand new secondary school in Nottingham – the Nottingham University Samworth Academy or NUSA.

One element of the architect’s design for the academy featured a cable supported, single skin clear ETFE roof over an unheated internal street. The roof’s main function, as well as providing a shelter, was to allow a high level of natural light to enter the street as it was going to be bordered by classrooms. The main contractor, Carillion plc, approached Base for its technical expertise to develop a solution that could deliver all the key functional and aesthetic effects in the architect’s proposal.

Base won the project on technical experience, by proposing a more robust single skin ETFE solution. By adapting the revolutionary TEXO® cladding system, designed by Tensoforma of Italy, Base proposed to deliver an innovative tensile fabric solution that would offer the required high light translucency (97%), while offering a 30-year design, life thanks to a more modular approach. Initially conceived as a vertical cladding panel, this was the first time that TEXO had been adapted as an alternative to a glazed solution by using single skin ETFE foil.

The design incorporates a single layer of ETFE foil mounted on an extruded aluminium frame, and uses a high tech plastomeric strip to keep the foil under constant tension, even under varying wind loads. The benefits of the system include a high translucency roof that is a fraction of the weight, and costs considerably less than a toughened glass alternative.

The TEXO® system is modular in that the frames can be built and covered in a controlled factory environment off-site and delivered as complete and finished units which are then fixed into a prepared structural steel frame and gutter system. As such the solution also offered a high degree of prefabrication, reduced expensive site time and featured low weight components, which greatly reduced the risk of damage to the ETFE foil and from injury on site.

Base undertook the complete design, manufacture and installation process, including the structural aluminium gutters and primary steel arches.

Base delivered a highly innovative solution that matched the aesthetic requirements with a robust build quality, offering a 30-year lifespan – all installed swiftly and cost-effectively, meeting the brief and budget. The architect was particularly delighted with the high light levels our solution achieved. The NUSA opened to its first pupils on Friday 4th September 2009, and the new building was officially opened by Dame Kelly Holmes DBE in September 2010.

Base Structures recently helped bring to life the street walkways of the O2’s new retail development, the Designer Outlet Village. A total of 8 canopy masts were positioned in its walkways, with 4,744 aluminium white diamond petals and 5300 white discs in two sizes suspended from stainless steel tensioned nets.

The final result is a stunning decorative ceiling giving the mesmerising impression of hanging petals, with the ‘tree trunks’ created using glued laminate beams.

We’re proud to be involved in such a unique project, working with a team over the course of 11 weeks to design, prototype and see the project through to a high-quality installation. We are really happy that the results speak for themselves, and visitors to the O2’s new Designer Outlet Village are now greeted with an impressive feature and visual effect that we hope will put a smile on shopper’s faces for years to come.

We are excited to announce a new city dressing service designing, creating and installing stunning displays in town centres and retail areas around the country.…

Our brief was to provide a spectacular bar for VIPs and artists to service the O2 Venue. The fabric structure consists of four interlocking domes, two entrance tunnels, one of which encloses a staircase, and three conical column claddings.

Barrisol was specified as an ideal material to cope with the complex architectural geometries of each panel. The fabric in the domes is back lit and LED lights are built into the tunnel frames. Base Structures coordinated the complex design and detailing of the scheme and provided the steel frame onto which the Barrisol panels were fixed.

The ambitious design was fully realized to provide a unique chill out zone.

The South Plaza is a 10 hectare site located between the Olympic Stadium and the Aquatics Centre, re-landscaped after the Games by James Corner Field Operations (responsible for the successes of the New York Skyline landscaping project).

Base were tasked with installing a steel cable system to suspend 86 perforated steel lighting globes inherited from the Olympic Games. Running the length of a tree lined boulevard the cables will eventually be virtually invisible within the tree canopies as they grow over the coming years, creating the illusion that the globes are floating above the walkway.

Two pairs of tensioned steel cables are used to suspend each globe, connected to steel masts carefully positioned between the trees in such a way that they blend into the landscaping. The effects at night are certainly dramatic when the glowing orbs highlight the route for pedestrians.

Originally used as a thoroughfare for spectators on their way to the Olympic Stadium, the South Plaza now boasts illuminated tree lined boulevards, play parks, a small performance amphitheatre and benches aplenty.

Ousedale School has been serving the community of Newport Pagnell, a small town within the borough of Milton Keynes, since 1963. In 2014 the school refurbished tired areas that included the History and ICT Block with a fresh, contemporary scheme. Extending the modern makeover outside, a fabric canopy was planned that would not only maximise the usable exterior space but to add an architectural flourish to the school grounds.

Drawing inspiration from our pre-designed, award winning Blencathra canopy we installed in nearby Campbell Park in Milton Keynes, we worked with the school to redesign the canopy to optimally suit their own requirements. A reduction in size from 16m to 12m resulted in the Blencathra 12m canopy that would sympathetically fit within the existing school landscape whilst still providing an impressive amount of shelter. Unlike it’s bigger brother in Campbell Park, the demountable side and rear walls were completely omitted to create a permanently open structure.

The canopy has proven to be a hit with the pupils and staff alike, providing a new focal point and an added sense of identity to the school grounds. A perfect lesson on the flexibility of tensile canopy design!