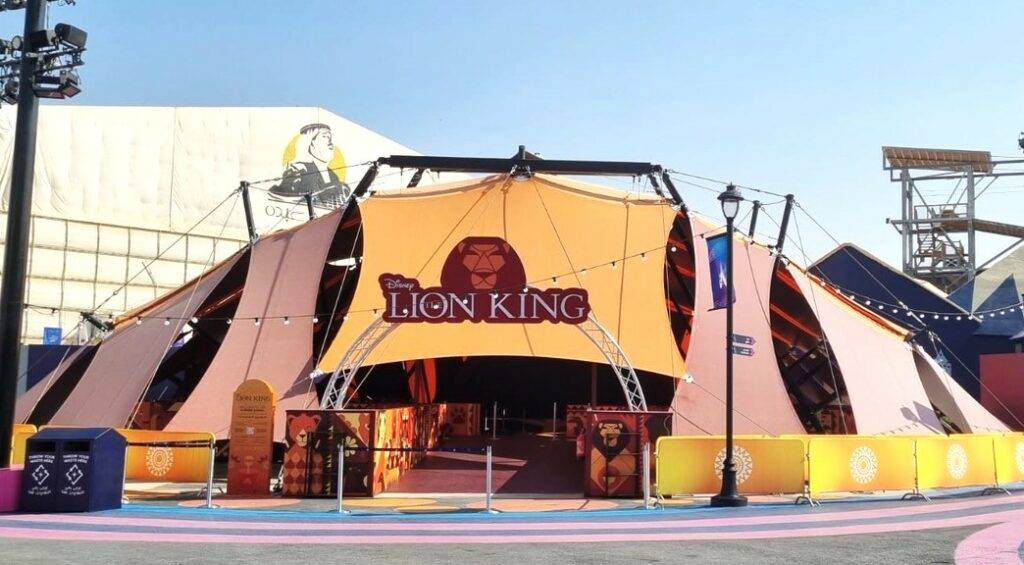

At Base Structures UK, we were honored to contribute to the creation of the mesmerizing venue of “The Lion King”, a musical immersive activation for Disney: The Castle, in Riyadh – a collaborative effort with Balich Wonder Studio and Disney Concerts.

“The Castle” is a musical experience that brings you closer than ever to the iconic music of Disney’s beloved animated worlds. At this magical family festival, celebrate music from Disney’s most popular animated films through captivating performances in immersive musical worlds and exhilarating concerts performed live on stage in front of the towering Disney Castle!

Tasked with providing fabric sails for a touring structure, our team seamlessly integrated with the client’s design, we provided essential engineering and detailed design assistance, leading to the precise patterning and fabrication of fabric membranes, complete with crucial cables and tensioners – in a tight 7-week timeline. Our site supervisors flew to Riyadh, ensuring a smooth on-site installation and briefing the client’s team on demounting procedures.

This success story was made possible through close collaboration with our partners, Balich Wonder Studio and Disney Concerts. Together, we transformed the venue of “The Lion King” into an immersive musical experience against the enchanting backdrop of the Disney Castle.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

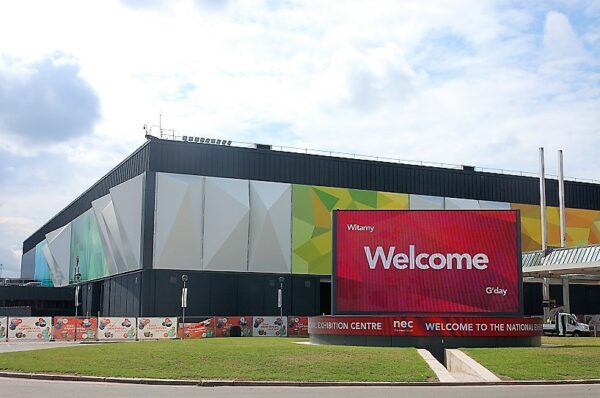

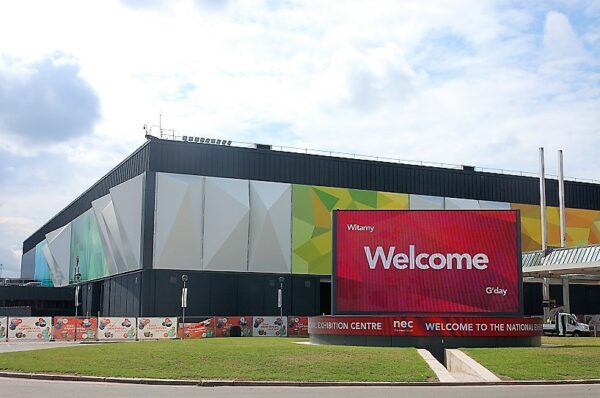

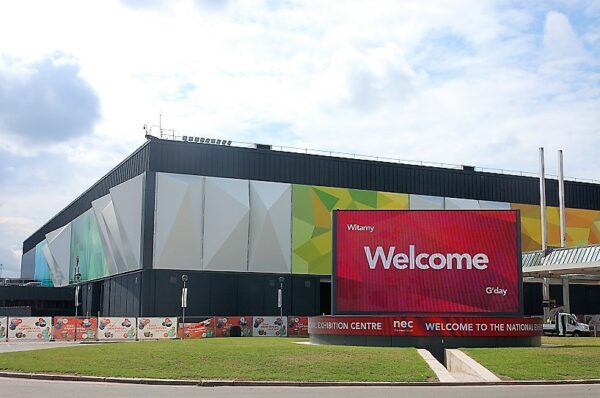

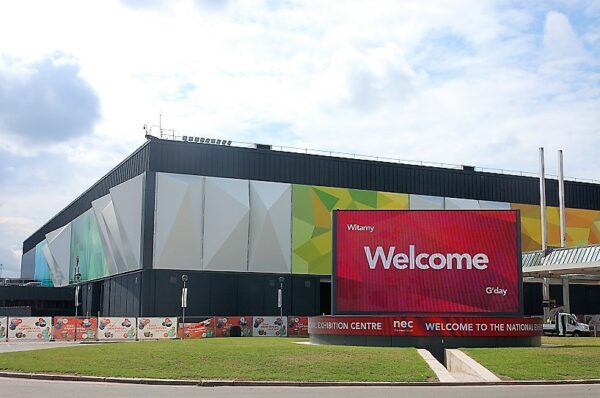

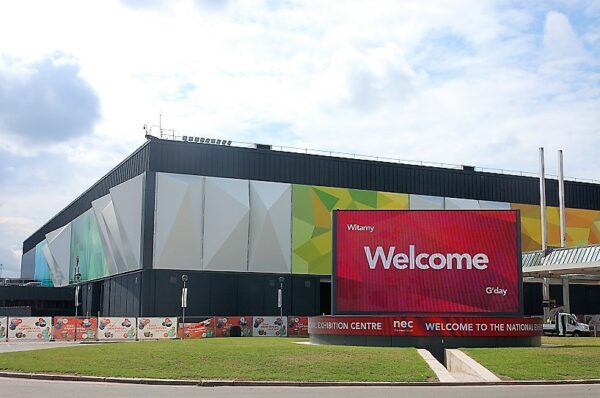

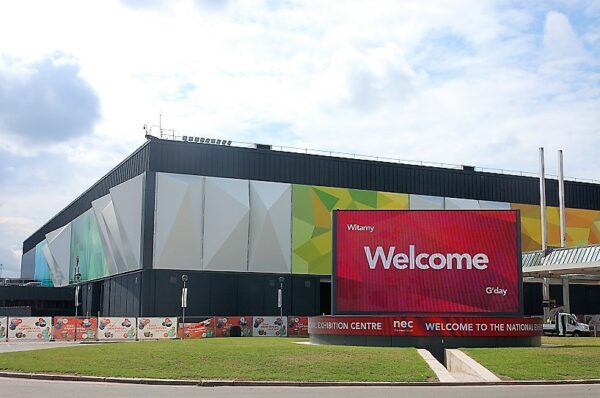

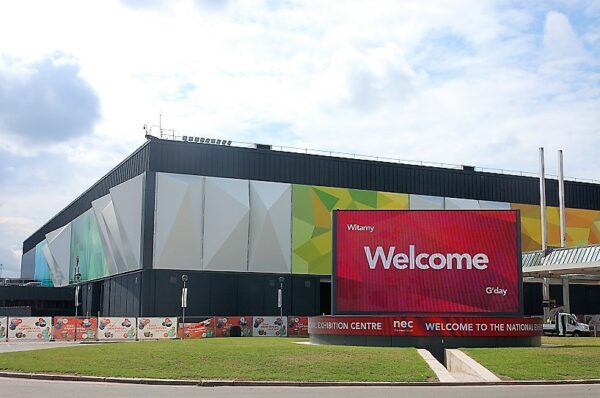

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

Glencar Construction approached Base to assist them with their prestigious project, building the new Moderna Innovation and Technology Centre based at Harwell Campus in Oxfordshire. This impressive build is set to be a new vaccine research, development & manufacturing facility.

The construction phase of the project is set to span late 2023 into 2024. To boost their works programme, Glencar were keen to utilise our temporary engineered weather screens to eliminate weather considerations from a typical build schedule.

Our brief was to install 59# tensile fabric screens, totalling 4400m², each bespoke in design, so they could be easily installed and demounted to the existing building with strategically placed webbing straps. Part of the brief was to ensure that the screens had minimal disruption to other site works and internal fit outs.

This was an incredibly fast-track project, from order to completion on site in just over 6# weeks! The client is very happy with the results, their site teams benefiting from an uninterrupted works programme and sheltered from the inclement autumns & winter weather.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

As part of their gym refurbishment, David Lloyd approached us to replace the fabric roof to their members pool in the Reading club. Utilising our expert fabric team, we carried out the safe dismantle and removal of the old membranes and associated components.

We then carried out a 3D survey of the structure to enable a re-design incorporating improvements to the replacement components.

Once the new bespoke fabric design was agreed we set about manufacturing and installing both the new inner and outer fabric roof membranes, all within a 2-week timeframe to ensure that the roof was re-installed as quickly as possible, and the pool closure time was minimal.

We also carried out cleaning works to the structural steelwork to give the whole pool area a fresh look for the refurbishment project.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

To prevent the pupils at the school from having to queue in the rain, our client Western Blueprint approached us to design and install an external canopy to the entrance of the School building.

The brief was for a simple and elegant solution, we recommended a revised version of our Brecon Walkway pre-designed canopy. We tweaked the original design, changing the scalloped edge to a straight edge for a sleek look to the canopy.

Base Structures designed, engineered, manufactured and installed the cream coloured PVC canopy and the integrated guttering solution.

The two stage bracketed design allowed for the brickwork to be reinstated around the first fix brackets, resulting in a tidier detail at the mounting locations.

The client was very satisfied with the end result with the canopy meeting the requirements for both weather protection and fitting into the aesthetic of the school courtyard.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

Concerned about the turning autumn weather the client was looking for temporary weather solution to enable them to secure the building and maintain their programme of works for the internal fit out of the new 15 storey office building in a prominent city centre location.

Base have previously installed temporary weatherproof screening on several large and prestigious construction projects to provide rain and wind protection for construction teams, enabling them to continue to work uninterrupted where building exterior is yet to be completed.

Tensile fabric screens can be installed quickly with minimal disruption to other site works. They are extremely adaptable and can be tailored to suit the access requirements. Base can also offer the option to have either vertical or horizontal webbing strap attachments, customising the screens to suit the interfacing options available within the space.

To provide a series of tensile fabric weather screens around the entire building perimeter, covering from the ground up to the 2nd floor. This would be an engineered solution allowing the client to assess the loads applied to the structure and have peace of mind that the screens are both weatherproof and also meet the sites prescribed wind loading.

The PVC flame retardant (B-S2-D0) fabric screens were proposed to be manufactured with horizontal welded webbing straps & ratchets at 1m centres providing attachments to tension the screens to the steel columns of the building, and the seams to be hot air welded to ensure completely watertight.

The entire project consisted of 44# screens with a total fabric area of 1800m2. The largest of the screens were 11m high by 8m wide. Some were split in two to provide a removable lower section allowing access when needed. Others were specifically adapted to fit around the personnel and goods hoists.

The screens each have a ground level weather flap that is timber battened to the existing concrete slab using 100mm frame fixings. Where screens abut with one another, they have vertical screen to screen weather flaps that were hot air welded together to form a weather tight seal.

Where fabric screens could not be tensioned laterally to columns, the design was adapted to tension vertically between the steel beams above and the concrete slab below. This was accomplished by utilising a pole and pocket detail top and bottom, with a steel plate bracket fixed to beam with lindaptors and eyebolts resin anchored to the concrete slab.

All panels are engineered to withstand the relevant British Standard wind loadings.

Fabric panel installation can become hazardous in wind speeds exceeding 10mph, be they steady or gusting. Weather conditions for the installation must be carefully considered during install planning and discussed fully with the client to understand any impact to programme.

There were several areas on the project where the existing columns were not able to be used to support the webbing strap screen fixings and alternative attachment methods had to be devised with the client.

Screens adjacent to bays that accommodated the hoists had to be adapted to fit around the hoist support scaffolding. In these locations, the screens had cut-outs to stop short of the hoist and their webbing tails were extended to fit through the hoist supports.

The clients project team were incredibly happy with the performance of the screens and the versatility offered by our solution which enabled them to adapt and match their fast-moving programme. Multiplex also found that Base Structures’ screening solutions were the most cost effective compared with alternative products they had reviewed and implemented on their other UK sites. Base’s screens also proved to be more versatile and offered more flexibility when considering site conditions and access requirements.

“Base have been excellent throughout the full process, from tender to installation. We have used a temporary weathering solution which is a great design and works perfectly. The installation team have maintained an extremely high standard of quality and safety and delivered the install ahead of the anticipated programme. I would highly recommend Base to any contractor looking for a temporary weathering solution. Well done to all.” The Client.

Once the client have completed their internal fit out works and ready to move onto the exterior and no longer require the screens, Base will remove them. Our screens are very quick to demount and, as with the installation, the operation causes minimal disruption to other site works.

From there Base will review the future of the screens as to their suitability for re-use, initially discussing with the client about any possible uses and if not look at our fabric industry and event industry networks to find a re-use. We have a zero to landfill policy and are committed to the upcycling and re-use of tensile fabric that has not yet reached the end of its life.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

In need of additional outdoor space, playground shade and weather protection, St Crispin’s School were looking for a series of three colourful outdoor canopies in the school grounds. McLaughlin & Harvey came to us for a solution.

The Mendip 4P 400 is a popular multi-functional canopy from our pre-designed range. It was the most appropriate structure for the project as they are perfectly suited for providing play shade, shelter and covered seating with an elegant yet simple design.

The result provides and increased amount of practical open-air space which can be utilised in many ways including outdoor leaning, school events and socialising areas.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

TFT Consultants approached us on behalf of the Glamorgan Cricket to replace the two membranes of the seating stand covers at the Sophia Gardens stadium as the original membranes had reached the end of their design life.

To give the stadium a fresh new look and renewed canopy lifespan for years to come, we removed both old membranes and supplied and installed new membranes to both the Croeso and Pro Steel Engineering Stands. We inspected the associated steelwork for suitability of re-use on both structures and re-furbished where necessary.

As part of our zero waste to landfill policy we used our network to find re-use opportunities for the old fabric, that whilst past its structural design life could still be used for many other applications, including wrapping timber for waterproofing.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

Having originally installed the fabric mesh façade to the Nova Leisure Centre in Prestatyn in 2015, we were asked to remove the 28 no. mesh screens and supporting aluminium extrusion temporarily to allow some much needed maintenance works to the existing building.

We then re-instated the mesh fabric screens once the refurbishment works had been completed.

The original installation was for ISG Construction and involved design, manufacture and install of the large fabric façade panels ranging in size up to 7m long, along with the associated fittings.

Located on the banks of the River Thames in Barnes, The London Wetland Centre brings the countryside into the Capital. Designated a Site of Special Scientific Interest in 2002, the wetlands are home to otters, peregrine falcons, bitterns and a multitude of other species – and all despite being under the main flight path for Heathrow Airport. In 2010 the WWT approached us to help create a brand new, high-tech ‘Pond Zone’. Bringing pond dipping into the 21st century, this outdoor attraction features a manoeuvrable underwater webcam and wide screen displays.

To ensure this educational facility can be used in all weathers, one of our standard tensile fabric canopies was specially adapted to provide an affordable solution. A Malvern 6P 1000 was fitted with stainless steel chains to attractively direct water to ground level, whilst a serpent hose on one corner channels rainwater into the pond itself.

With green steelwork and cream PVC, this tensile fabric structure creates a natural yet stylish addition to the wildest corner of the Capital city.

Passenger comfort is essential to the whole 21st Century travel experience and so it is that bus stations are coming of age. Gone are the diesel streaked, wind-swept naked expanses of concrete and tarmac inhabited only by pigeons, drunks and unfortunate late night travelers. Nowadays passenger embarkation terminals are state of the art architectural landmarks that have more in common with the best hotels than ghost towns, and now Wolverhampton Bus Station is no different after commissioning a PTFE roof for it’s terminal.

Wolverhampton is the latest city to have invested in passenger welfare by constructing three steel and glass boulevards, sealed against the elements with 6000m2 of architectural fabric that has been especially profiled to minimise the roofs intrusion onto the cityscape beyond.

The daytime translucency of the fabric and night time feature lighting ensure the friendly ambience is maintained 24 hours a day.