As part of a larger renovation and face lift to Manchester’s iconic Printworks leisure destination area of the city centre, the team at John Tuner Construction came to us to develop three separate fabric schemes to internal and external elevations for the Printworks renovation.

Internally, our fabric experts worked very closely with the client and a local artist to develop a 210m2 printed fabric facade design that would achieve the stunning new visual needed for this very prominent location. Installing a façade of this size around a corner called for specialist manufacture and installation to create the seamless aesthetic of the finished artwork.

The client required the artwork to be framed by a flashing surround with hidden fixings which we were able to achieve using innovative brackets and connection details. Also internally, fifteen speaker panels were produced as part of a flush façade. These were engineered to be removable and held with magnets to again hide all fixings on the elevation.

Externally on Dantzic Street, we produced five large printed fabric screens showcasing the entertainment and activities on offer at Printworks. There was no room from a crane due to Dantzic street being narrow and in close proximity to the tramlines, so we had to design a steel frame in sections that could be installed by hand.

This was a challenging project we were working alongside the installation of a record breaking scale LED ceiling screen and the fabric façade features directly underneath this. Our installation experts worked alongside other contractors to develop a smooth system of work for an efficient and quality build, that would be ready in time for the grand opening in March 2024.

Visitors to the new look Printworks will find the new space fully immersive with visually stunning including our fabric façade taking pride of place within this updated venue, now ready for a brand new programme of events and other possibilities.

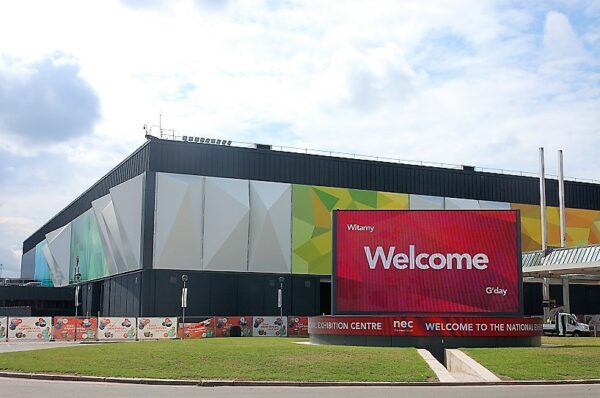

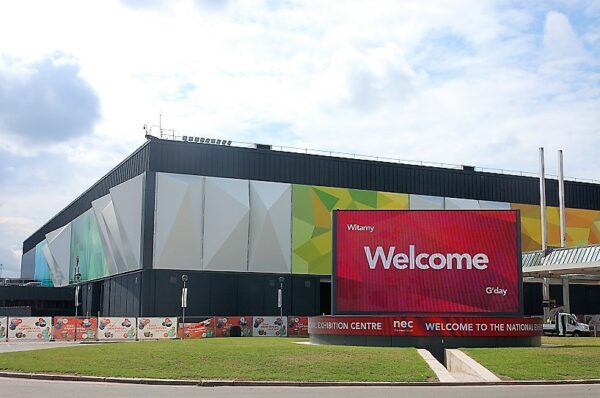

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

City placemaking is the art and design of creating public spaces and is often driven by community projects. Whether that’s through decorative art installations, creating…

As part of the ICON development to expand the logistics park at Manchester Airport to make it one of the largest in Europe, we were approached by Winvic Construction to develop a mesh cladding scheme for the five storey car park being built to supplement the new warehouse and offices of Plot 1.

Our solution involved a fabric mesh cladding system comprising of 14no. panels with its supporting aluminium extrusion interface that would fit to the steel frame of the multi storey car park.

The 960m² fabric mesh cladding offers greater protection from the elements and busy urban environment, extending the lifespan of the building as well as providing additional weather protection for the carpark users.

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Bethell Construction approached us to help them develop a canopy scheme as part of their ongoing regeneration works with the Manchester Airport transformation team and the redevelopment of Terminal 2.

The Meet and Greet valet parking service was to be relocated to T2 and required Base to design, supply and install a new canopy. To reduce queuing times, the new structure required 3 lanes with internal cameras and scanners to scan car registrations as they arrived at the terminal.

We developed the detailed scheme with structural design engineers Fenton Holloway & steel fabricators Sheetfabs to include the primary steel structure, fabric interface extrusion system, 2 PVC roof panels, 4 wall panels, 2 gable end panels and a bird proofing system.

The client and Base are very pleased with the resulting robust, practical and attractive canopy to service the parking customers at the terminal.

Following a fire at the Bus Station in which large areas of the existing tensile roof structure was damaged beyond repair, Base Structures were commissioned to remove the fire damaged areas of fabric, survey the existing steel and assess for structural damage, and then to replace all damaged fabric elements with new and make good the finished tensile structure.

The existing roof is made up of a double skin PTFE multi barrel-vaulted structure contained within a large, essentially triangular, outer ring beam. All fabric elements were fixed to the steel structure via luff track or clamp plates.

An aluminium facade contains the guttering and gives a nice finished appearance to the entire perimeter.

The client required to provide a degree of weather protection to an open atrium courtyard for the Hulme High Street Shopping Centre in Manchester.

The PTFE canopies have perimeter upstands to allow rainwater to be collected and channeled down to ground level, allowing shoppers to stay fairly dry and happy!

Located in Crown Square, Manchester, this 196m2 single inclined conic fabric canopy structure was to feature as the latest part of the Spinningfields development – an area that is fast becoming known as the ‘Canary Warf of the North’. By providing both a focal point and shelter for outdoor events, the tensile fabric canopy needed to lend an entirely new identity to an area surrounded by tall, modern buildings.

Highlighting the benefits of using tensile fabric structures for exterior performance areas, this bespoke fabric canopy structure demonstrates the versatility, practicality and aesthetic possibilities of tensile fabric for extending the use of public spaces. Designed to fit onto existing foundations located at different levels, the undulating fabric perimeter and inclined steelwork present a lively aesthetic in keeping with the vitality of the wider location.

Large advertising hoardings are not everyone’s cup of tea but in terms of sheer scale this one takes the biscuit! At over 6000m2 of roadside advertising area, this project was widely lauded as the largest Out Of Home opportunity available in the UK at that time. Sitting adjacent to the main arterial route from the M60 into Manchester and exposing full frontal glory to the new City of Manchester Stadium, this is one bill board that is impossible to ignore. Exposure was even claimed for airline passengers on the flight path into Manchester Airport!

During the planning application process our client had to guarantee to the Gas-o-meter owners Transco, that clothing the structure would in no way detract from it functioning as originally intended. Therefore prior to receiving approval, extensive structural engineering calculations were produced which predicted that by wrapping the skeletal steel frame within a web of suitably tensioned stainless steel cabling the structure would not deflect sufficiently to stop the rise and fall of the gas chamber within. Thankfully the calculations were spot on and the resulting fully clothed gas holder continued performing unhindered and as unabashed as it had when naked!

An additional USP of this site was that the cable net devised for carrying these super large printed banners allowed for quick, 8-hour removal and re-installation of the media so that a pair of eyes seeing it on the way to work in the morning would be exposed to a different campaign on the way home in the evening. Striking visibility has always been the life blood of the advertising industry.

Clever, simple, functional and high spec – all the buzz words that Abito attribute to their Salford Quays waterside development. So they thought, what better than to literally top off their brand new residential apartment building than a dramatic and striking tensile fabric architectural centrepiece.

Elegantly perched on the rooftops like a proud toupee, our fabric roof structure covers the central atrium with the tensioned fabric allowing a diffused light into the well of the development. Defining themselves as the creators of affordable yet chic urban living, it is these aesthetic finales that create the talking points Abito rely on to keep their buildings one step ahead of their market competitors.

Manchester International Festival (MIF) is an artist-led, commissioning festival which presents new works from the performing arts, visual arts and popular culture. As part of the 2009 festival, Zaha Hadid Architects was commissioned to design a contemporary salon to house solo performances of Johann Sebastian Bach’s music. The installation was to be housed in a 25m x 17m ‘black box’ in the Manchester Art Gallery. Zaha Hadid Architects responded with a stunning design consisting of a 110m long white ribbon which would wrap itself around both the stage and the audience, creating a dynamic yet intimate performance space.

Zaha Hadid is one of the most extraordinary, innovative and creative designers to work with textile architecture. Each piece designed by her team is a head turning, award winning revelation. We have collaborated on a number of projects and each time our creativity in design and manufacture as well as the technical capabilities in the fabric are challenged to their very limits. The results are awe inspiring brilliance.

Jack Thompson, Technical Director, MIF

Tracey Low, Senior Producer, MIF

Melodie Leung, Architect, Zaha Hadid Architects

Gerhild Orthacker, Architect, Zaha Hadid Architects

Kevin Hemmings, Architect, Base Structures

Andy Traynor, Installation Director, Base Structures

Tony Hogg, Engineer, Tony Hogg Design

Benedict Whybrow, Designer, Tony Hogg Design

Michael Whitcroft, Acoustic Engineer, Sandy Brown Associates

Nick Croker & Paul Thomas, Site Supervisors, Base Structures

Having already successfully collaborated on the Serpentine Gallery project, Zaha Hadid Architects approached Base to gain the team’s technical expertise on the design’s buildability – with the performance of the ‘ribbon’ being pivotal to its function. Transport ability was another consideration for Base, as the installation would also be reinstalled in other venues.

Base’s recommendation was to combine a light aluminium frame with a stretch Lycra® fabric skin. With preliminary costs coming within budget, Zaha Hadid Architects commissioned Base to develop the design through to cost certainty.

The first challenge for Base was to transform the architect’s complex 3D model into a buildable structure that retained all the fluidity of the original design. With the help of experienced tensile engineers Tony Hogg Design, Base constructed a framework that replicated the model exactly. And to be certain of the fabric’s suitability, Base fabricated and wrapped a prototype section of the frame to test fabric compensations.

For the ‘ribbon’ to perform as intended, it was imperative that a smooth change of curvature was maintained throughout the structure. So Base’s solution featured a series of eye shaped rib frames, connected with a top and bottom rail each rolled to a specific radius. Speed of installation was essential too, so turned nylon spigots were employed to connect the frames with a push fit connection. Likewise the fabric was designed to be applied rapidly by only having nine ‘fields’ which were zipped together with a discrete plastic closure, utilising Base’s expertise from the banner finishing side of its business.

The frame was hung by 2.5mm stainless steel cables from suspension points in the gallery ceiling, incorporating an easy to adjust fastener. Base also supplied the stage platform and fitted rigid acoustic reflector panels inside parts of the ribbon, directed by acoustic engineers, Sandy Brown Associates. The structure was installed in three days with two teams of four riggers, working day and night shifts.

The result was a single continuous ribbon which swirled around one of the main rooms in the Manchester Art Gallery, creating layered spaces cocooning both performers and the audience. Base’s successful realisation of Zaha Hadid Architect’s design was largely due to the combined experience of the team, ranging from engineering; detail design; fabrication of the frame; assembly of the fabric; and the professional site crew. The project’s triumph was also recognised by one arts critic in particular, stating that the structure not only worked as a sculptural object but acoustically as a chamber music venue. The structure has since visited the Amsterdam Festival in 2010 and is due to continue its tour, scheduled for a visit to Abu Dhabi in March 2011.