Glencar Construction approached Base to assist them with their prestigious project, building the new Moderna Innovation and Technology Centre based at Harwell Campus in Oxfordshire. This impressive build is set to be a new vaccine research, development & manufacturing facility.

The construction phase of the project is set to span late 2023 into 2024. To boost their works programme, Glencar were keen to utilise our temporary engineered weather screens to eliminate weather considerations from a typical build schedule.

Our brief was to install 59# tensile fabric screens, totalling 4400m², each bespoke in design, so they could be easily installed and demounted to the existing building with strategically placed webbing straps. Part of the brief was to ensure that the screens had minimal disruption to other site works and internal fit outs.

This was an incredibly fast-track project, from order to completion on site in just over 6# weeks! The client is very happy with the results, their site teams benefiting from an uninterrupted works programme and sheltered from the inclement autumns & winter weather.

Construction projects can be complex affairs, with many different teams converging on small, often tight spaces to carry out the necessary work in time. Alongside…

One of our key environmental objectives is zero waste to landfill. When working on the early stages of a fabric structure, this is a key…

When we put fabric structures up, we do all we can to ensure their lifespan is as long as it can be. The key to…

Concerned about the turning autumn weather the client was looking for temporary weather solution to enable them to secure the building and maintain their programme of works for the internal fit out of the new 15 storey office building in a prominent city centre location.

Base have previously installed temporary weatherproof screening on several large and prestigious construction projects to provide rain and wind protection for construction teams, enabling them to continue to work uninterrupted where building exterior is yet to be completed.

Tensile fabric screens can be installed quickly with minimal disruption to other site works. They are extremely adaptable and can be tailored to suit the access requirements. Base can also offer the option to have either vertical or horizontal webbing strap attachments, customising the screens to suit the interfacing options available within the space.

To provide a series of tensile fabric weather screens around the entire building perimeter, covering from the ground up to the 2nd floor. This would be an engineered solution allowing the client to assess the loads applied to the structure and have peace of mind that the screens are both weatherproof and also meet the sites prescribed wind loading.

The PVC flame retardant (B-S2-D0) fabric screens were proposed to be manufactured with horizontal welded webbing straps & ratchets at 1m centres providing attachments to tension the screens to the steel columns of the building, and the seams to be hot air welded to ensure completely watertight.

The entire project consisted of 44# screens with a total fabric area of 1800m2. The largest of the screens were 11m high by 8m wide. Some were split in two to provide a removable lower section allowing access when needed. Others were specifically adapted to fit around the personnel and goods hoists.

The screens each have a ground level weather flap that is timber battened to the existing concrete slab using 100mm frame fixings. Where screens abut with one another, they have vertical screen to screen weather flaps that were hot air welded together to form a weather tight seal.

Where fabric screens could not be tensioned laterally to columns, the design was adapted to tension vertically between the steel beams above and the concrete slab below. This was accomplished by utilising a pole and pocket detail top and bottom, with a steel plate bracket fixed to beam with lindaptors and eyebolts resin anchored to the concrete slab.

All panels are engineered to withstand the relevant British Standard wind loadings.

Fabric panel installation can become hazardous in wind speeds exceeding 10mph, be they steady or gusting. Weather conditions for the installation must be carefully considered during install planning and discussed fully with the client to understand any impact to programme.

There were several areas on the project where the existing columns were not able to be used to support the webbing strap screen fixings and alternative attachment methods had to be devised with the client.

Screens adjacent to bays that accommodated the hoists had to be adapted to fit around the hoist support scaffolding. In these locations, the screens had cut-outs to stop short of the hoist and their webbing tails were extended to fit through the hoist supports.

The clients project team were incredibly happy with the performance of the screens and the versatility offered by our solution which enabled them to adapt and match their fast-moving programme. Multiplex also found that Base Structures’ screening solutions were the most cost effective compared with alternative products they had reviewed and implemented on their other UK sites. Base’s screens also proved to be more versatile and offered more flexibility when considering site conditions and access requirements.

“Base have been excellent throughout the full process, from tender to installation. We have used a temporary weathering solution which is a great design and works perfectly. The installation team have maintained an extremely high standard of quality and safety and delivered the install ahead of the anticipated programme. I would highly recommend Base to any contractor looking for a temporary weathering solution. Well done to all.” The Client.

Once the client have completed their internal fit out works and ready to move onto the exterior and no longer require the screens, Base will remove them. Our screens are very quick to demount and, as with the installation, the operation causes minimal disruption to other site works.

From there Base will review the future of the screens as to their suitability for re-use, initially discussing with the client about any possible uses and if not look at our fabric industry and event industry networks to find a re-use. We have a zero to landfill policy and are committed to the upcycling and re-use of tensile fabric that has not yet reached the end of its life.

Construction projects can be complex affairs, with many different teams converging on small, often tight spaces to carry out the necessary work in time. Alongside…

One of our key environmental objectives is zero waste to landfill. When working on the early stages of a fabric structure, this is a key…

When we put fabric structures up, we do all we can to ensure their lifespan is as long as it can be. The key to…

The project brief was to supply a tensile roof structure and fabric walling which could incorporate doors and see through panels to form this large temporary building in Miami, Florida.

Using fabric for the roof and walls provided diffused lighting and a soft ambience to create the desired environment in which the client could hold a Victoria’s Secret fashion show. The fabric panels proved to be a great architectural solution, catering for all the client’s needs in a short time frame.

The Royal International Pavilion at Llangollen was originally built in 1992 as a combined sports facility and auditorium to host the famous International Eisteddfod. The fabric had become tired and worn over time, and a gradual change in the type of end use left Denbighshire Council looking to both renew the fabric and improve the weathering properties of the auditorium. A temporary summertime extension, which is used for the Eisteddfod and other events also required renewal.

Removing the existing fabric was a carefully staged operation, planned to maintain the structural stability of the building during the process. As the original design information was somewhat sketchy and in some cases lost in the mists of time, Base Structures were required to carry out a full 3D survey of the fabric contact points and use this information to re-model the form, both on the main auditorium and the extension canopies. The new membranes were then assembled in our Bristol factory, and transported to site and installed with great care in a complex lifting operation.

The completed work has given this landmark building a new lease of life, leaving it looking better than ever.

Large advertising hoardings are not everyone’s cup of tea but in terms of sheer scale this one takes the biscuit! At over 6000m2 of roadside advertising area, this project was widely lauded as the largest Out Of Home opportunity available in the UK at that time. Sitting adjacent to the main arterial route from the M60 into Manchester and exposing full frontal glory to the new City of Manchester Stadium, this is one bill board that is impossible to ignore. Exposure was even claimed for airline passengers on the flight path into Manchester Airport!

During the planning application process our client had to guarantee to the Gas-o-meter owners Transco, that clothing the structure would in no way detract from it functioning as originally intended. Therefore prior to receiving approval, extensive structural engineering calculations were produced which predicted that by wrapping the skeletal steel frame within a web of suitably tensioned stainless steel cabling the structure would not deflect sufficiently to stop the rise and fall of the gas chamber within. Thankfully the calculations were spot on and the resulting fully clothed gas holder continued performing unhindered and as unabashed as it had when naked!

An additional USP of this site was that the cable net devised for carrying these super large printed banners allowed for quick, 8-hour removal and re-installation of the media so that a pair of eyes seeing it on the way to work in the morning would be exposed to a different campaign on the way home in the evening. Striking visibility has always been the life blood of the advertising industry.

Having approached Base structures about a similar scheme at the outset of the works, Dublin Airport came back to us in October 2008 with a proposal to close off the southern elevation of the building with two and a half thousand square metres of weatherproof fabric.

After receiving the brief Base set about designing, manufacturing and installing this completely bespoke and fully engineered solution in less then seven weeks, with the site install time barely exceeding two of these.

This speed of service, combined with the durability, weatherproofing and reliability of the installed scheme enabled the construction team to recover time on the €609m project and made a significant contribution towards completion on the May 2010 deadline.

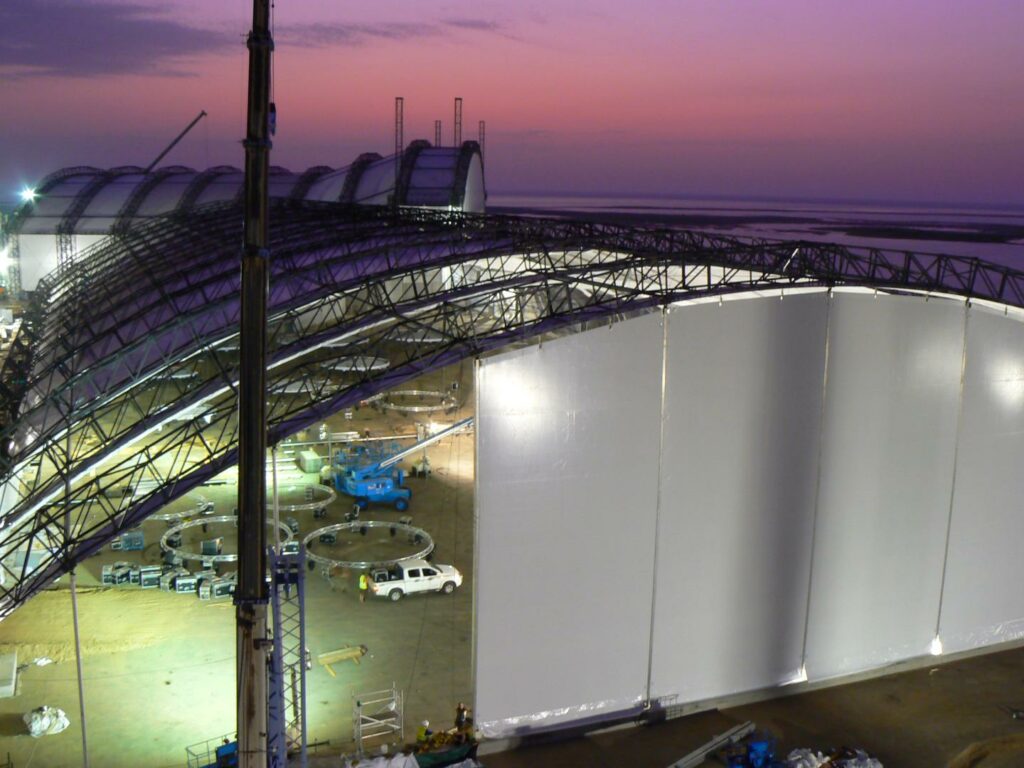

Base Structures won the contract with ESS to design, manufacture and install the tensile fabric roof and wall panels to the Dining Hall pavilion (the largest of the three temporary structures on the site). All work had to be completed in time for the opening ceremony of the King Abdullah University of Science and Technology which is situated in Saudi Arabia. The project consisted of the Gable panels to the end elevations, Truss Infills and twelve 86 meter long ground-to-ground PVC Roof Panels, each of which incorporated 13 meters of transparent PVC to one end.

An important consideration in the design of this structure was the intense daytime heat which can sometimes exceed 70°C. To ensure the integrity of the keder edge (which joins the fabric panels to the steel supporting structure), EPDM rubber keder cord was used in place of the traditional PVC cord as it has a much higher melting point. All of the fabric was installed in a four week period by our installation teams working in the 40°C relative cool of the Arabian night.

The result of this was a 13 meter high picture wall which ran the complete length of one side of the entire structure, displaying the spectacular view across the harbour at sunset to the King’s guests.

Having completed the construction of the two iconic No. 8 Towers at Stratford’s East Village, Mace required removal of the temporary fabric cladding that had been used during the build to provide sheltered working areas.

Base Structures UK planned and executed a comprehensive and safe method of work for the dismantling of the PVC screens and associated fixing from these two soaring 113m and 127m high towers.

We provided a team of expert fabric technicians Rope Access personnel who specialise in working at height to set about removing the fabric panels.

Before the removal of the temporary screens, we had worked with the client at the design development stage of the fabric wrap under a pre-contract service.

The Highways Agency anti-corrosion programme for the Severn River Suspension Bridge requires the sealing of the cables with Hypalon fabric wrapping. Initially we supplied rope access labour to assist with the wrapping work but whilst on site we soon realised that the process could be much improved with the use of an inflatable welding blanket.

Using technologies developed through out core business of manufacturing Tensile Fabric Structures, we designed, manufactured and supplied a solution incorporating an air cushion that when pressurised, formed itself onto the surface of the main cable whatever the size or shape. This system successfully speeds up the de-humidification process and improves the quality of weld and has been widely adpopted within the bridge cable wrapping industry.

We completed the first phase of these works in 2007 but this is an ongoing project with further phases of work and many more bridges and cables to go!

Our brief was to install temporary wraps to the columns at the entrance of Tate Britain, as a special feature linking in with the David Batchelor artwork exhibition taking place at the time. The wraps acted not only as an advertisment for the exhibition but were a vibrant and imaginative use of the existing buildings architecture.

The project was more complicated than it looked as each natural stone column is unique and therefore each one had to be individually surveyed by our climbers before patterning the fabric to suit. We manufactured the wraps from fabric printed to the colours specified by the artist and installed them at night, once again using ropes access techniques. The Tate Britain Museum were extremely pleased with the result of the finished product and the high quality.