Atkins Global approached Base, seeking our assistance with the design, fabrication, and installation of a 4.7 x 7m multi-use stage canopy as part of the redevelopment for Cardiff’s big Canal Quarter project.

Working with the main contractor Knights Brown, we proposed a bespoke and elegant looking canopy, incorporating their desired elements for lighting and rainwater collection, fulfilling the client’s vision for this project.

The dock feeder canal has been revitalised by the excavation of the central reservation along Churchill Way, and Base’s canopy stands out as a striking focal point amidst the newly installed rain gardens and outdoor seating area in this high-quality, multipurpose, regeneration project.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

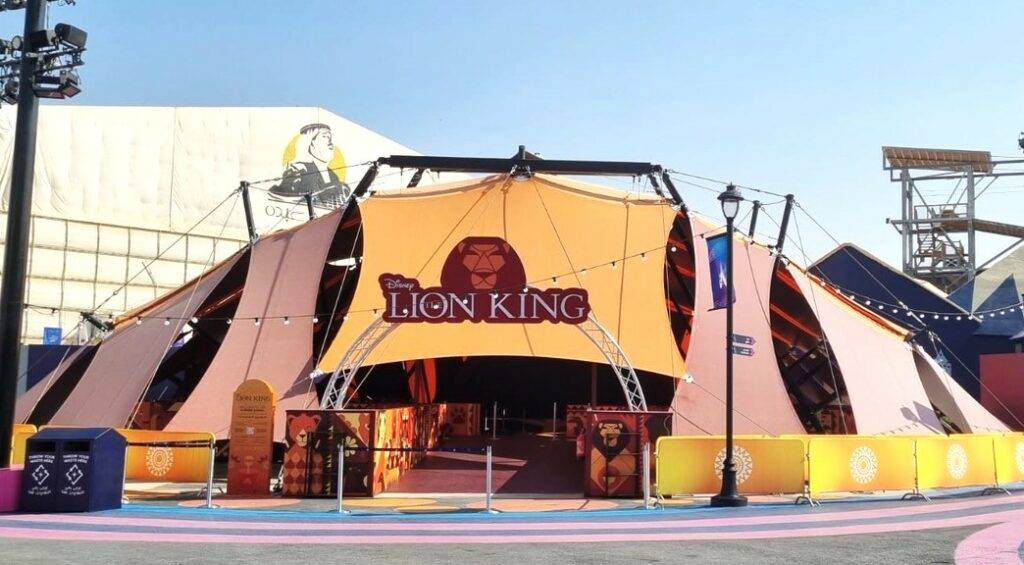

At Base Structures UK, we were honored to contribute to the creation of the mesmerizing venue of “The Lion King”, a musical immersive activation for Disney: The Castle- a collaborative effort with Balich Wonder Studio and Disney Concerts.

“The Castle” is a musical experience that brings you closer than ever to the iconic music of Disney’s beloved animated worlds. At this magical family festival, celebrate music from Disney’s most popular animated films through captivating performances in immersive musical worlds and exhilarating concerts performed live on stage in front of the towering Disney Castle!

Tasked with providing fabric sails for a touring structure, our team seamlessly integrated with the client’s design, we provided essential engineering and detailed design assistance, leading to the precise patterning and fabrication of fabric membranes, complete with crucial cables and tensioners – in a tight 7-week timeline. Our site supervisors ensured a smooth on-site installation and briefing the client’s team on demounting procedures.

This success story was made possible through close collaboration with our partners, Balich Wonder Studio and Disney Concerts. Together, we transformed the venue of “The Lion King” into an immersive musical experience against the enchanting backdrop of the Disney Castle.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

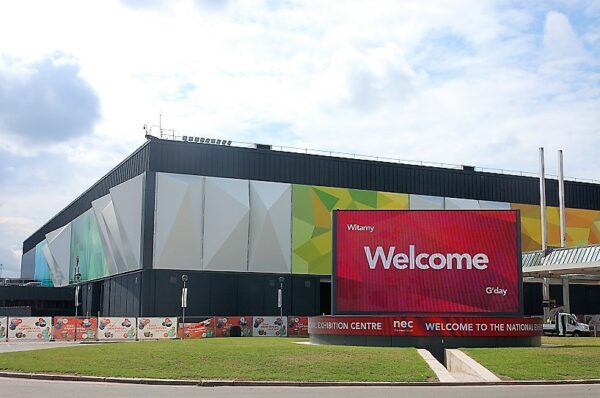

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

As part of their gym refurbishment, David Lloyd approached us to replace the fabric roof to their members pool in the Reading club. Utilising our expert fabric team, we carried out the safe dismantle and removal of the old membranes and associated components.

We then carried out a 3D survey of the structure to enable a re-design incorporating improvements to the replacement components.

Once the new bespoke fabric design was agreed we set about manufacturing and installing both the new inner and outer fabric roof membranes, all within a 2-week timeframe to ensure that the roof was re-installed as quickly as possible, and the pool closure time was minimal.

We also carried out cleaning works to the structural steelwork to give the whole pool area a fresh look for the refurbishment project.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

TFT Consultants approached us on behalf of the Glamorgan Cricket to replace the two membranes of the seating stand covers at the Sophia Gardens stadium as the original membranes had reached the end of their design life.

To give the stadium a fresh new look and renewed canopy lifespan for years to come, we removed both old membranes and supplied and installed new membranes to both the Croeso and Pro Steel Engineering Stands. We inspected the associated steelwork for suitability of re-use on both structures and re-furbished where necessary.

As part of our zero waste to landfill policy we used our network to find re-use opportunities for the old fabric, that whilst past its structural design life could still be used for many other applications, including wrapping timber for waterproofing.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

We were very excited to be approached by the Architect Michael Mallinson to help develop a canopy for the Community of Omdurman, in Khartoum, Sudan (images taken at the Inaugural Event of the Khalifa House Museum, Community Tent).

With average daily temperatures of 44 degrees the community was in need of a shaded and well ventilated event space for community meetings and gatherings.

Base designed and engineered the scheme for approval by the Director of the Khalifa House Museum Niemat Mohamed. The design consists of an array of rolled steel arches fabricated and site welded by a local shipbuilder.

Between the arches is a tensioned grid of steel cables onto which is woven 50mm wide strips of polypropylene to form a shade canopy. The plastic strip is used locally to form the woven base of Angareb beds.

The modern design of the shade structures has links to the traditional domed tens of the Baggara Nomads who tie colourful woven mats onto a lightweight timber scaffold. The shade structure design is being repeated at other museum sites in Sudan.

Funding Partners

British Institute in Eastern Africa

British Council Cultural Protection Fund

Ministry of Digital Media, Youth & Sports

Aliph Foundations

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

The team at John Sisk & Sons working on the newly built Pelletstown Railway Station, approached us to help them with a triple canopy scheme that would provide ample bicycle shelter space for the commuters and travellers and allow greener use of public transport.

We created a bespoke design for each of the three canopies. The steelwork frames were manufactured in the UK and installed by SISK. The PVC fabric membranes and associated fixings and fittings were installed by Base Structures.

Along with the logistical challenges of travel restrictions between UK and Ireland at that time, summer 2021 during the Covid-19 Pandemic, we also had the challenges of working next to a live railway line into our safety procedures.

The end result is an attractive suite of highly functional fabric canopies that will improve the travelling experience for travellers and make it more practical and environmentally friendly for people to travel to the station by bicycle.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

The Forum at the University of Hertfordshire College Lane Campus is undergoing a significant redevelopment to include new social facilities and expansion of the teaching space.

The Main Contractor for the redevelopment project, Wilmot Dixon, asked us to design, supply and install an external fabric entrance canopy at The Forum to form part of this expansion.

Part of the brief was for the structure to be free-standing and not connected to the building. Our solution was an attractive bespoke L-shaped barrel-vaulted canopy that would achieve the required roof coverage area for the new outdoor space.

The result is an eye-catching structure expanding the space ready for the improved teaching and socialising experience at The Forum.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

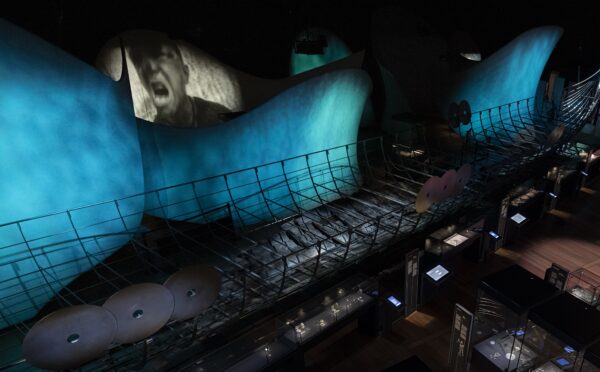

Event Communications Ltd approached us to help them develop a series of 9 fabric wave sculptures to embody the water element of the new Viking exhibition, menacingly titled The Raid!, and which opened June 2021. The waves help create a dynamic & natural flow for visitors as they follow the tour.

Our solution utilised similar details from a project we were proudly involved in with Zaha Hadid, the JS Bach Music Hall – Zaha Hadid | Base Structures, and encompasses a light aluminium modular framing system. Double skinned stretched spandex fabric, patterned specifically for the complex organic geometries, provides a soft sense motion and defines the exhibit space the museum were looking for.

The finished fabric forms add theatre to the installation with a sense of the ocean to fit with the origins of the Vikings. A separate blackout skin fitted between the spandex allows the museum to project imagery onto the fabric as part of the exhibit and because of the modular design, the structures can be used again for future exhibitions.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

Trepassey care home had been undergoing extensive redevelopment involving a series of extensions and garden terraces. So our client approached us to provide a barrel-vault canopy to the new landscaped garden. The canopy was to double as a covered seating area for the residents to enjoy the attractive surroundings and to provide a 52m door to door sheltered walkway to protect from the elements.

A continuous series of tensile PVC fabric canopies comprising 15 bays, supporting steel masts and rolled arches. Also with PPC aluminium extrusions and electro-polished s/s membrane plates. This allowed us to achieve the curvature required to fit the garden shape and crescent walkway path accurately.

A structure like this in an elevated position overlooking The Wirral will withstand inclement weather conditions and provide a robust shelter and shade. Because of this the residents will be able to spend more time outside for fresh air and safe distanced socialising.

Over the years, Base Structures have installed numerous sun shade canopies, which are versatile tensile fabric structures that provide shelter from all the elements as…

Whilst social distancing is no longer a requirement, we now face new challenges with soaring energy bills for homes and businesses alike heading into the…

With 2023 being one of the wettest years on record and January 2024 one of the warmest, councilors and developers across Continental Europe in both rural…

Edinburgh Airport’s commercial team approached us to help them develop several landside canopies as part of their new East Terminal project. The scheme comprised of two long pedestrian walkway canopies adjacent to the taxi zone, a small bus stop canopy and a large terminus canopy.

We developed and the detailed the schemes with design engineers Tony Hogg Design & Scottish based steel fabricators Miller Fabrication, to include the primary steel structures for all canopies, fabric interface extrusion system and 44no. PVC fabric roof membranes.

The result is a series of visually impressive fabric structures providing an enhanced passenger experience to this historic terminal development project.