Arup approached Base to be involved in this ground breaking project for Urban-Air Port and Six Miles Across London Ltd (small.) to install the first Vertiport to serve as a drone hub called Air One. This structure is the blueprint for the first of many as Urban-Air Port have ambitious plans to install around 200 Vertiports worldwide in the next 5 years.

Base designed, manufactured and installed the external fabric cladding roof & wall panels as well as the internal drum wall window panels, circumjacent to the moveable FATO drone launchpad in the structure’s centre. A number of other elements within the structure were also provided by Base, including a polycarbonate pelmet, skirt and door surrounds.

With multiple trades and designers involved in this complicated & intricate project, collaboration & coordination was key to making it a success. With an incredibly tight installation programme, there was no scope for error, and we were pleased to successfully install our element of the project on programme & in only 4 weeks!

The final result is a stunning 17,000 ft² structure that will be a great showcase to launchpad an example of Urban-Air Port’s plans for more Vertiports.

One of our key environmental objectives is zero waste to landfill. When working on the early stages of a fabric structure, this is a key…

When we put fabric structures up, we do all we can to ensure their lifespan is as long as it can be. The key to…

There is no doubt that many of the changes our communities have had to make around Coronavirus restrictions are staying put for a while yet.…

Located in the heart of England at Twycross Zoo, The Gruffalo Discovery Land has been developed in partnership with brand managers Magic Light Pictures and is inspired by the best-selling picture book The Gruffalo written by Julia Donaldson and illustrated by Axel Scheffler. The aim of the four-acre experience is to educate and inspire the next generation about conservation – something that is critical to the future of many species as well as the planet.

Wates Smart Space working with Twycross Zoo approached us to help them develop a scheme for a new replacement Owl Aviary at the zoo. With a recent increase in avian flu at the time, the zoo were concerned about cross contamination with other smaller native wild birds.

We worked with the team at Wates to identify a more suitable finer mesh that would prevent other birds from entering the enclosure, and significantly reduce the risk of transmission.

We designed, engineered and erected the timber frames, stainless steel knit mesh, keepers vestibules, owl boxes and two gates as part of the project.

The result is a more robust owl enclosure that helps prevent risk of cross contamination whilst still maximizing habitat space and animal welfare.

The Gruffalo Discovery Land at Twycross Zoo is open from Saturday 9th April 2022. To buy tickets, go to www.twycrosszoo.org/the-gruffalo-discovery-land

One of our key environmental objectives is zero waste to landfill. When working on the early stages of a fabric structure, this is a key…

When we put fabric structures up, we do all we can to ensure their lifespan is as long as it can be. The key to…

There is no doubt that many of the changes our communities have had to make around Coronavirus restrictions are staying put for a while yet.…

Base Structures were originally approached by the Zoo to offer their expertise to design an enclosure and aviary solution for a number of new home’s for Sumatran orangutans, Sulawesi macaques, Rhinoceros hornbill’s and Bali starlings, on the new £40m development, Island Projects, at Chester Zoo.

The main focus as always with any type of zoo enclosure is on the animal welfare, therefore very careful consideration was given on the selection and approach for the mesh netting, to ensure these critically endangered and beautiful species were provided with a safe and secure environment.

Utilising our network of specialist suppliers, we were able to select the appropriate stainless steel mesh product, and design an interface solution with other substrates on the enclosure, in a way that the orangutan in particular could not unpick or find a weakness.

The macaque enclosure, and hornbill and Bali starlings aviaries although less challenging, specific detail still had to be considered with regard to minimal visual impact, and a protective and secure environment for the apes and birds.

All of the enclosures and aviaries were delivered on time and to programme, through some challenging weather conditions, and the end client was extremely satisfied with the end result, that is the animals of course!

As part of a project housing for an existing zoo enclosure, Base Structures were asked to find the perfect solution for Bristol Zoo’s flamingo aviary.

For this project, we were able to provide the materials and expertise to wall and roof this structure in Polypropylene knotless mesh.

The resultant complete refurbishment of the area provides the flamingos with a lifelike habitat and for the public, an exciting walk through structure.

A large walk-through aviary structure was needed for the popular visitor attraction, Birdworld in Farnham, Surrey. This project was to be designed as a seashore zoo enclosure to house nesting Hammerkop, waders and other coastal birds that are part of the international breeding program, helping to ensure the survival of their species.

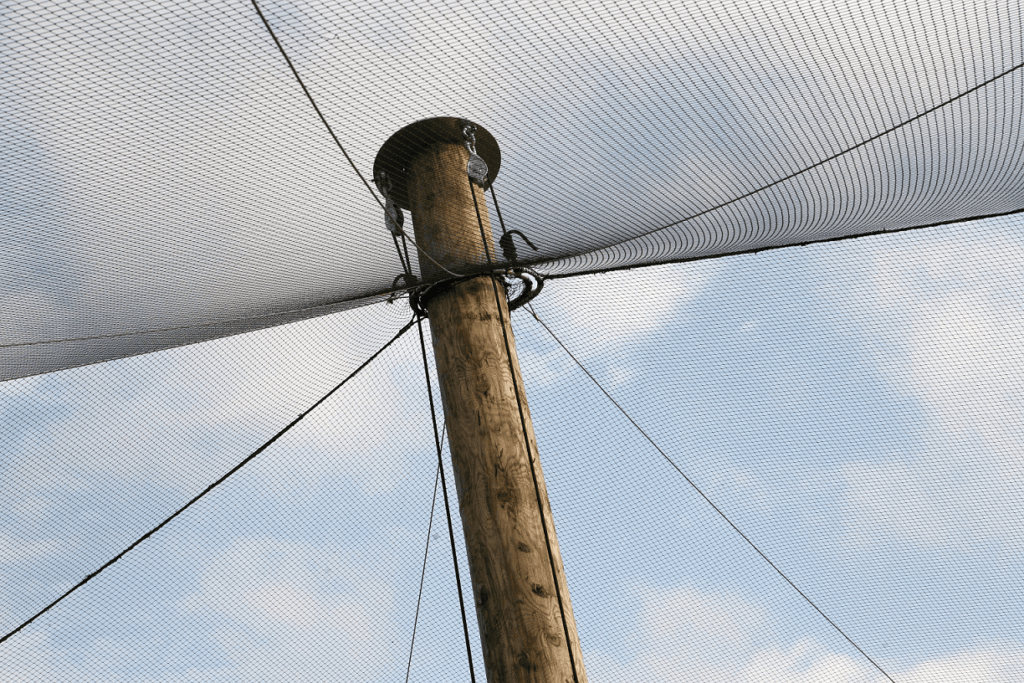

We decided to use tough 25x25mm knotted fire-rated polyethelene as it is a visually unobtrusive material, almost creating an invisible effect. A primary design feature for this aviary is that the netting is designed to be easily raised and lowered from within the enclosure by a system of ropes and pulleys. This provides incredibly easy access to the netting for maintenance and repair without the inconvenience of using access machinery, ensuring time and cost savings for the entire future of the structure.

Another key consideration in designing and installing this aviary was for it to have as low an environmental impact as possible, in both it’s material specification and construction techniques. Therefore, fully engineered timber posts were selected to support the netting and installation techniques were used that required no concrete for the foundations, making huge environmental savings.

With the help of their new visually appealing and environmentally friendly enclosure, the coastal birds live on!

Back in 2002 we installed this very unique net structure to create the Living Coast Aviary for Paignton Zoo, it is a multipurpose aviary housing several species of bird from waders and penguins to auks and terns. It also ads a dramatic visual to the attraction for visitors and to the Torquay coast skyline.

Since then we have been providing regular maintenance to the structure and in particular at the end of 2016 completed a 6 year programme of gradually upgrading the structural components to extend the lifespan of the aviary. This included replacing the cable rope with PVC coated cable and replacing most of the net panels, the result is that this 15 year old structure is essentially brand new again.

The installation was mostly carried out using rope access techniques. It was a great success and we are very pleased to have been involved in this landmark project.

The Aviary is a very effective structure which both Vector and Paignton Zoo are very happy with.

Polyethylene net in this coastal location does require regular maintenance and upgrading, but over all is still considerably more economical than stainless steel mesh yet just as effective. We can provide this ongoing maintenance service and have highly skilled industrial rope access and fabric technicians, see bottom right images of our technicians carrying out maintenance works.

For our clients who run and manage zoos, animal welfare is their top priority. Most zoos exist as an opportunity not just for the public…

The Wildfowl and Wetlands Trust approached Base Structures with a specific problem for their proposed new exhibit housing Redshanks and Avocets. They needed a world class enclosure that did not feel enclosed, had an exceptionally low environmental impact and was as affordable as possible to construct, install and maintain. A fundamental requirement was also for the fabric of the structure to be wader bird friendly; these species are very fragile and if spooked can easily damage themselves on solid obstructions.

Paul Pattison, Development Projects Officer, Slimbridge WWT

Andy Traynor, Project Manager, Base Structures

To provide as natural an environment as possible, the enclosure uses tough 25x25mm knotted polyethelene, a surprisingly unobtrusive material that is not visually dominating. From inside the enclosure the netted walls appear to be almost nonexistent against the surrounding landscape, providing an incredibly natural environment for the birds. This is enhanced by the supporting timber posts and netting surfaces being installed at various angles, creating a natural effect with no perpendicular lines, helping to minimise the man-made appearance of the enclosure. To offer protection to the delicate wading birds the supporting timber posts around the edge of the enclosure are all placed outside the netting, preventing possible injuries if the birds are scared into flight.

The biggest environmental savings were achieved by using construction techniques that did not require the use of any concrete. As such, the supporting structure was installed using alternative foundation techniques that did not literally cost the earth. Fully engineered timber posts hold up the entire net structure, providing the necessary support with a natural, renewable material that is no more intrusive within the enclosure than a few slender trees.

A key requirement from the Trust was to ensure that the structure would be as economical as possible to maintain in the future. As a critical design requirement from the very beginning of the project, we managed to engineer a solution into the structure that alleviated the need for carrying out inspection or repair at any great height. We achieved this with a very simple system; the netting is attached to metal rings that are slightly larger in diameter than the structural timber posts, these rings are hoisted up and down the posts by a system of ropes and pulleys from ground level – being simply tied off to hold the netting in final position. Thus the whole netting structure can be easily and quickly lowered down the supporting timbers for any work to be carried out at ground level, ensuring significant costs for the lifetime of the structure.

We worked closely with the Trust to supply this enclosure in kit form, allowing them to use their own equipment and expertise to install the structure with minimal supervision from ourselves. Our comprehensive survey provided the exact locations and angles for the timber posts, after these were installed by the Trust we fitted the cabling, in turn enabling the Trust to install the netting themselves and complete the installation. Once installation was successfully completed the team at the Trust had also gained the necessary experience to undertake any future maintenance themselves.

The Trust are thrilled with their new visitor attraction, the cost savings achieved in construction and the knowledge that the enclosure will continue to perform in the future for minimal outlay. The birds have settled in superbly and exhibit their natural behaviour, presenting visitors with a privileged experience; to see the birds acting naturally at close quarters without feeling you are confined in a restricted space. The Trust have commented that they hope the birds may eventually breed, a sure sign of success! This would then become an even bigger attraction for visitors, helping to develop visitor empathy and fondness for the birds which is beneficial to the broader WWT conservation efforts.