Base Structures were commissioned to design, manufacture and install the departures tensile canopy scheme, one that would provide a truly stunning entrance to the new Terminal. As one of the first areas of Terminal 5 encountered by passengers, it was absolutely essential that we created a world class structure that made an exceptional first impression.

Andy Dearman, Architect, Pascall and Watson Architects

Paul Yates, Laing O’Rourke

Mark Randerson,SH Structures

Mark Smith, Project Manager, Base Structures

Duncan Baird, Site Supervisor, Base Structures

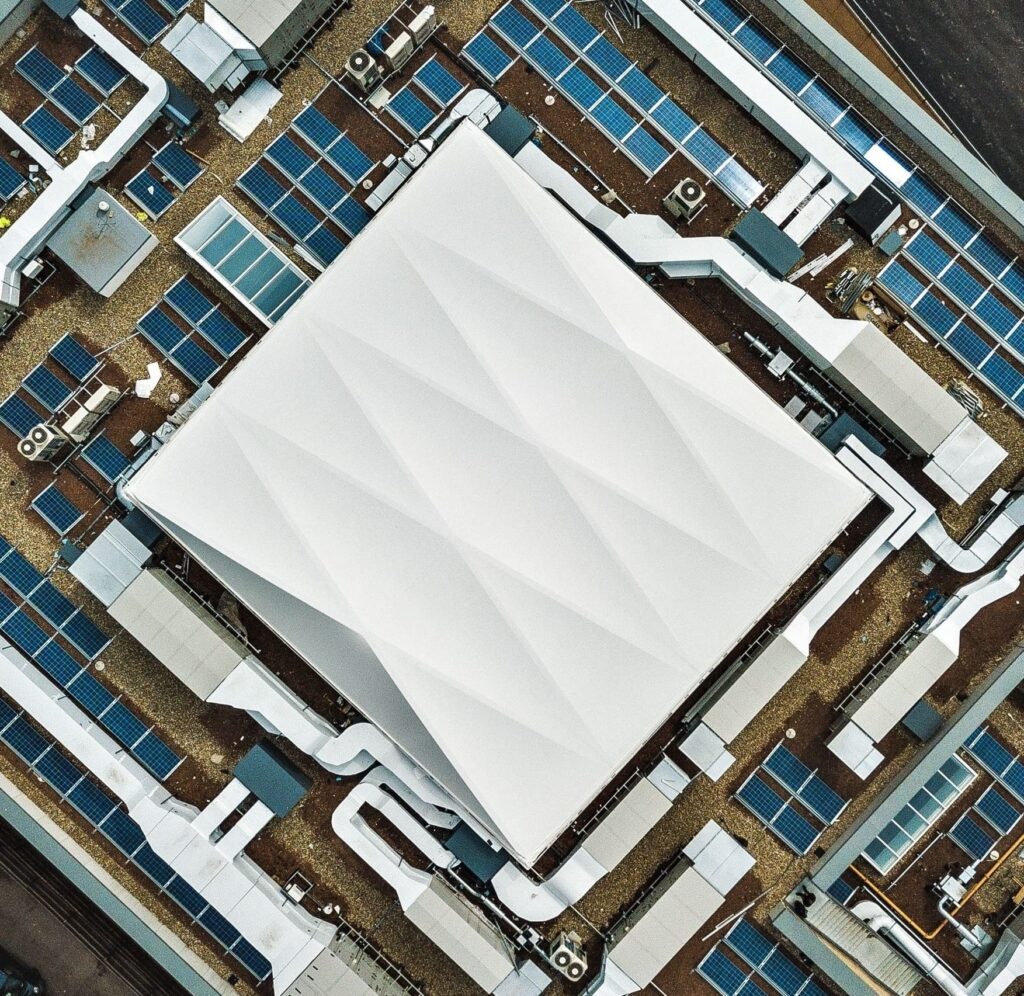

The project consisted of over 4000sqm of PTFE tensile fabric canopies that extended the whole length of the set down lanes at the terminal entrance. Additional canopies in the package included the car park entrance structures that reflected the main scheme. The eye-catching design utilises several series of a twisted hypar arrangement tensioned on an architectural steel frame complete with bespoke lighting. The sweeping undulations of fabric serving not only as shelter for passengers underneath but also as an outstanding architectural flourish to the terminal building.

A major contribution to Base Structures winning this tender was by partnering with a well respected steel fabricator from the beginning of the project. As the value of the steel exceeded the fabric content a more competitive price was achieved by having the steel fabricator as the lead contractor.

PTFE fabric was chosen instead of PVC to bring a number of benefits including increased translucency, higher strength, improved fire rating and a lower susceptibility to dirt. Being far more difficult to manufacture and install than PVC however required specialist skills to ensure the longevity of the structure was not compromised; poorly manufactured and installed PTFE will quickly fail. The accuracy and quality of the design, manufacture and installation are critical to the success of this material; when all these disciplines combine successfully PTFE has an exceptional life span as a tensile fabric.

As well as supply and fit of the fabric membrane Base were also responsible for installing the steelwork, fitting steel cladding to the lighting arms, installing bespoke lighting equipment and co-ordinating all works on site.

The installation was challenging and had to be completed in time for the grand opening of the terminal in March 2008. Our installation team were working on-site continuously for eighteen months, finally culminating in a seventeen man team for the last six months to ensure we could bring the project in on time.

The execution of the manufacture and installation reflected the high quality of the design and the expectations for the gateway to be the country’s new showcase terminal. The project was completed in plenty of time for the official opening of Terminal 5 by the Queen on 14th March 2008, finally opening to the public on 27th March 2008.

We designed and installed this very aesthetically pleasing courtyard roof at the newly built Hounslow Town Primary School.

The school wanted weather protection for the courtyard but also to ensure it remained an outside space, so the canopy was designed with openings around the edge.

The lattice criss-cross structure is constructed from carbon steel sections and spans from East to West. The fabric has been treated with Nano which is hydrophobic, giving the fabric good self-cleaning properties.

Although our client was sited in a campus of high architectural quality buildings there was a desire to introduce more informality in order to improve the working experience.

Alongside the introduction of a fabulous coffee cart, meeting pods and nature inspired wall graphics we were asked to provide an array of suspended leaves in their three storey atrium. To avoid a forest of suspension cables a stainless steel net was tensioned between columns at high level allowing each leaf to be on a single drop cable.

The leaves were UV ink jet printed with designs representing the changing colours of the seasons and were grouped in three arrays. The fabric selected was a PVC coated glass cloth mesh that has acoustic properties helping to keep noise levels down for those enjoying the newly invigorated space.

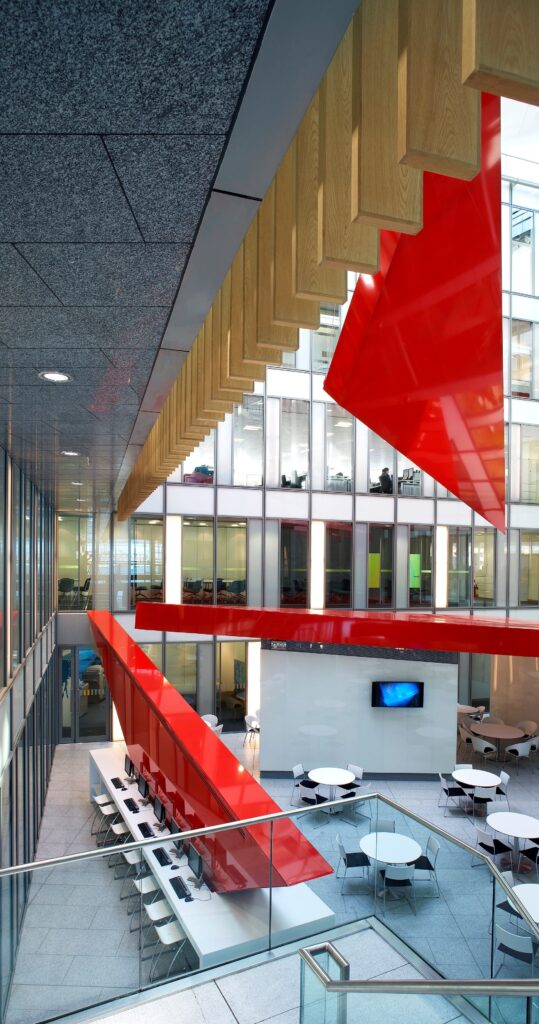

Architects LOM designed four large tensile fabric ‘shards’ forming a sculptural interpretation of the bank’s red logo for the atrium of their Dublin head office in Grand Canal Square.

In collaboration with Stretch Ceilings UK, Base coordinated the design of all the steel rafts as well as the fabrication and suspension of the largest hanging shard. The dramatic shapes which dominate the space were achieved with our unique combination of design, manufacture and rope access installation skills.

Our client approached us to assist them with a PVC roof structure over a Salt Barn that had reached the end of its lifespan.

We carried out a methodical removal of the old roof and gable panel and supplied and installed a new 1200m2 panel to the structure.

Given the size of the panel and the tricky crane lift this produced, the installation was particularly challenging during a windy autumn period. Further challenges presented were ensuring the salt was kept dry between the removal and replacement of the roof.

With a fixed deadline and delivery of several thousand tonnes of salt looming, we had to work swiftly and efficiently, using the old removed fabric to provide temporary protection.

In the summer of 2012, Bristol based artist Jan Blake received a commission for a new installation inspired by the suspended silk sculpture ‘New Leaf’ which we helped Jan create in 2005 for the DEFRA HQ in London. A ‘visionary outside-in, inside-out spatial perspective’ inspired by Architect John Tiah, this time the suspended artwork was to be installed a little further from home in Beijing, China.

Using the same construction methods as before but to a slightly smaller scale, we patterned and manufactured the natural silk organza fabrics and fitted them to bespoke steel frames. After Jan had worked her artistic magic by individually hand dyeing the leaves in her studio, they were carefully crated at our Bristol Factory and shipped to Beijing where they were met personally by Jan and her team of specialist riggers who carried out the delicate install.

Commissioned by The Art Management Specialist in Hong Kong, a series of twelve hand painted silk leaves measuring 3.5 metres long by 1.6 metres wide now tumble down from the atrium ceiling of the Indigo Shopping Centre.

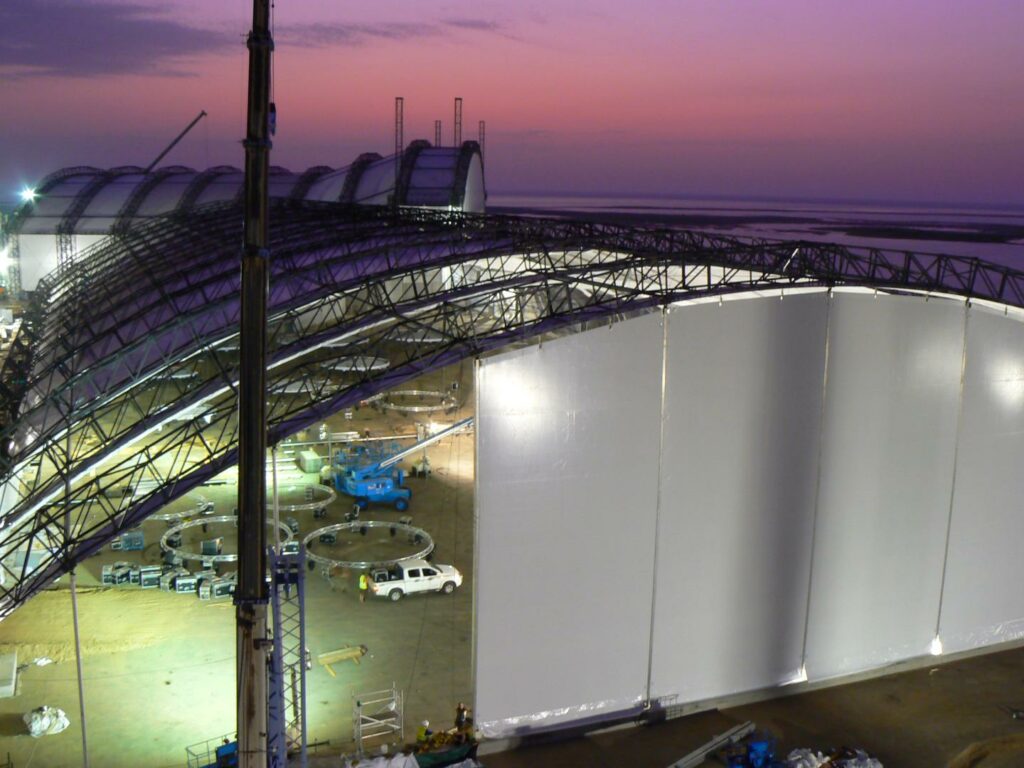

Base Structures won the contract with ESS to design, manufacture and install the tensile fabric roof and wall panels to the Dining Hall pavilion (the largest of the three temporary structures on the site). All work had to be completed in time for the opening ceremony of the King Abdullah University of Science and Technology which is situated in Saudi Arabia. The project consisted of the Gable panels to the end elevations, Truss Infills and twelve 86 meter long ground-to-ground PVC Roof Panels, each of which incorporated 13 meters of transparent PVC to one end.

An important consideration in the design of this structure was the intense daytime heat which can sometimes exceed 70°C. To ensure the integrity of the keder edge (which joins the fabric panels to the steel supporting structure), EPDM rubber keder cord was used in place of the traditional PVC cord as it has a much higher melting point. All of the fabric was installed in a four week period by our installation teams working in the 40°C relative cool of the Arabian night.

The result of this was a 13 meter high picture wall which ran the complete length of one side of the entire structure, displaying the spectacular view across the harbour at sunset to the King’s guests.

The beginning of 2019 brought a lot of stormy weather to Liverpool docks and left Liverpool Port Authority warehouse looking a little worse for wear. We are no strangers to the Liverpool docks site as back in 2013 Base Structures designed and manufactured the 22,000m² of tensile fabric that covers the warehouse skeleton steel structure.

A small amount of damage was sustained from within the building that wasn’t attended to promptly, the stormy weather came, picked and pulled at the cladding. The devastation is all too clear in the pictures below.

Base was called in to assess the structure. We then stabilised the cladding to prevent further damage from the second storm that was expected a few days later.

We removed all damaged components, re-instated where we could, replaced what was not serviceable and ultimately brought the structure back to life.

As tensile structures such as this are an investment we do recommend regular maintenance to ensure they fulfil their design life and continue to look good.

Back in 2002 we installed this very unique net structure to create the Living Coast Aviary for Paignton Zoo, it is a multipurpose aviary housing several species of bird from waders and penguins to auks and terns. It also ads a dramatic visual to the attraction for visitors and to the Torquay coast skyline.

Since then we have been providing regular maintenance to the structure and in particular at the end of 2016 completed a 6 year programme of gradually upgrading the structural components to extend the lifespan of the aviary. This included replacing the cable rope with PVC coated cable and replacing most of the net panels, the result is that this 15 year old structure is essentially brand new again.

The installation was mostly carried out using rope access techniques. It was a great success and we are very pleased to have been involved in this landmark project.

The Aviary is a very effective structure which both Vector and Paignton Zoo are very happy with.

Polyethylene net in this coastal location does require regular maintenance and upgrading, but over all is still considerably more economical than stainless steel mesh yet just as effective. We can provide this ongoing maintenance service and have highly skilled industrial rope access and fabric technicians, see bottom right images of our technicians carrying out maintenance works.

For our clients who run and manage zoos, animal welfare is their top priority. Most zoos exist as an opportunity not just for the public…

Stunning architecture has become a trademark of the modern Olympic and Paralympic Games, with environmental credentials being of paramount importance. As such these three structures are not only at the forefront of contemporary design, they are also fully demountable and relocatable, amply fulfilling these criteria. Together they hosted the Shooting, Paralympic Shooting and Paralympic Archery events. The set consisted of the 25 meter, Combined 50 & 100 meter and the Finals Shooting Ranges.

Each event structure is individually identified by the bright discs of colour which are set into the high and low points that create the undulations in the facades. The Orange themed Finals building measures in at a massive 25m x 47m x 50m, requiring 16,000m2 of fabric to fully clothe it inside and out. The Magenta themed Combined Range measuring 10m x 20m x 106m, requires 9,000m2 of fabric and the blue themed 25m Range building measuring 25m x 55m x 10m, 5,000m2. The high level discs incorporate ventilation openings whilst the ground level ones identify doorways for ingress through similarly coloured tunnels to the sporting arenas.

IFAI International Achievement Award 2013 Winner.